Neutron Physics Laboratory – Horizontal Channels

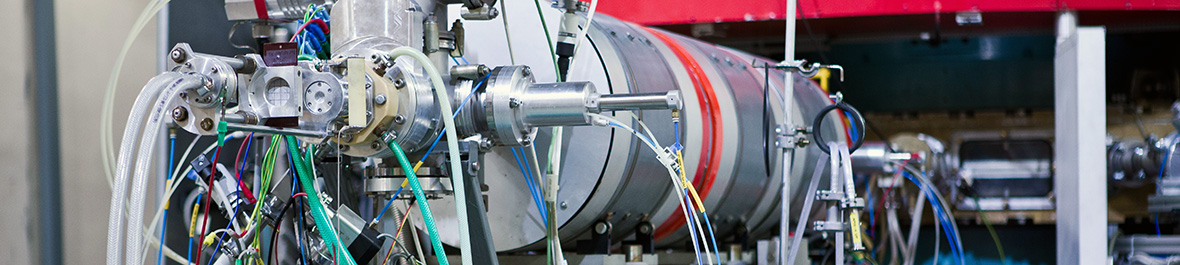

Neutron Physics Laboratory (NPL) was founded in the frame of NPI in order to perform neutron-physics experiments according to the NPI research programme as well as to provide experimental facilities and research experience to external users in the open access mode. The neutron channels hired at nuclear research reactor LVR-15 are employed for materials research using neutron diffraction as well as for experiments in nuclear physics and for neutron activation analysis.

Fundamental and Applied Research with Neutrons

Research with help of neutrons is carried out at five horizontal thermal-neutron beam channels and at vertical irradiation channel of the medium power light water research reactor LVR-15 which are hired from the Research Centre Řež, Ltd. Neutron Physics Laboratory (NPL) uses moderate flux of neutrons for neutron scattering experiments, for nuclear analytical methods and for fundamental nuclear physics. The activity of the Neutron Physics Laboratory is focused basically in two directions:

Scattering of neutrons is used to study structure of materials in various size scales, from ordering of atoms in crystal lattice to microscopic heterogeneities on nano- and microscopic scales. High penetration of neutrons in most materials permits to carry out these tests non-destructively in the bulk and/or inside special sample environment (low and high temperatures, mechanical load).

Nuclear reactions of neutrons with matter are employed to analyze concentrations or concentration profiles of elements in solids as well as for fundamental nuclear physics.

NPL instruments at the research reactor LVR-15

Neutron beams at horizontal channels

Five neutron scattering instruments are installed at four horizontal thermal neutron channels (HK4, HK6, HK8 and HK9) and serve primarily to research in the fields of material science and solid state physics. In addition, one horizontal channel (HK3) hosts special beamline for neutron depth profiling, prompt gamma activation analysis and fundamental nuclear physics.

Neutron Activation Analysis at vertical irradiation channel

Nuclear spectroscopy techniques are exploited by Group of Instrumental Neutron Activation Analysis. This group is involved in the development of advanced neutron and photon activation analysis procedures, in both non-destructive and radiochemical modes, and their applications in multidisciplinary research, namely in environmental, biomedical geo- and cosmo-chemical sciences.

Access for external users

Neutron Physics Laboratory offers open access to its facilities for external users. Modalities of the access are the following:

- Open access through the proposal system.

- By establishing a cooperation with a NPL scientist on a NPL-supported research programme (i.e. in-house experiments). Contact the particular instrument responsible in case of interest for such a cooperation. Nevertheless, also the in-house research projects should undergo the proposal submission procedure (long-term proposal).

- Using beamtime quota allocated to a particular facility in the frame of bilateral contracts.

- For commercial purposes, paid service can be provided. Users from private and industry sectors can arrange purchase of the access to NPL facilities. Test measurements and Feasibility studies can be offered free of charge before a commercial experiment is agreed.

European projects

CANAM-NPL infrastructure was a partner in several European infrastructure projects.

During 2015-2019, the H2020 project SINE2020 created an innovation-friendly environment around European neutron sources by coupling research and innovation. CANAM-NPL infrastructure was a partner in SINE2020 project, among others also in its work package "Industry Consultancy".

Many of the experiments carried out in the past using neutron beams were performed by research groups in the frame of international Open access supported by NMI3 projects in the frame of FP6 and FP7 programmes. For example, NPL participated in the access programme in the frame of FP7 NMI3-II project (Integrated Infrastructure Initiative for Neutron Scattering and Muon Spectroscopy).

Experimental investigations in this field are concentrated on experimental studies of the dispersive monochromators providing high and ultra-high angular and/or energy resolution. We have done several tests of ultra-high resolution dispersive monochromators based on multiple reflections excited in elastically deformed perfect crystals. High-resolution monochromatic neutron beams also opened new possibilities of application for an alternative radiography technique, for the so called phase contrast radiography.

History

The studies in the field of Bragg diffraction optics has in NPI ASCR, v.v.i. a long tradition starting by investigations of neutron diffraction by ultrasonically vibrating perfect and nearly perfect single crystals and followed by investigations of neutron diffraction by cylindrically bent perfect crystals. In the last decades many papers have been published in which successful employment of curved perfect Si or Ge crystals as neutron monochromators or analyzers in particular diffraction experiments have been reported. It has been found e.g. that due to the spatial condensation of neutrons (because of asymmetric diffraction geometry or focusing in real space), at the sample position one may obtain a high monochromatic beam density comparable or higher than that of the mosaic monochromators. Taking into account reflectivity and the resolution properties of curved crystals Popovici et. al. from Missouri University demonstrated a feasibility of the optimized curved crystal three axis spectrometer for inelastic neutron scattering which had the properties generally better than those of spectrometers employing flat mosaic crystals. New interest in the reflectivity and focusing properties of curved perfect crystals has been evoked also by successful testing of the bent perfect crystals employed in double-monochromator systems, or for medium and high resolution small-angle scattering diffractometers. Favourable properties of the bent Si or Ge crystal for short wavelength monochromatization have also been reported. Furthermore, very efficient original double and triple axis arrangements employing bent perfect crystals have been proposed and then tested for residual stress measurements of polycrystalline materials. In the last decade the neutron diffraction group of NPI ASCR, v.v.i. has been concentrated on the development of new unconventional types of focusing neutron monochromators permitting significantly to increase figure of merit of some dedicated neutron scattering instruments and also on development of the so called dispersive monochromators based on multiple reflections realized either in one bent perfect crystal or by means of sandwich of two curved crystal slabs.

Prospects

However, in spite of the successful use of the focusing techniques in the field of neutron scattering, their potential has not yet been fully explored. The tools necessary for their implementation have yet to be developed, especially when the whole design of the diffractometer system must be individually considered. A large open area still exists in the field of inelastic neutron scattering, powder diffractometry, neutron reflectometry and particularly in TOF diffractometry and spectrometry. The possibility of using the neutron Bragg diffraction techniques based on the elastically deformed perfect crystals elements for the TOF experiments has appeared highly demanded in relation to new neutron sources and projects as ISIS (England), J-Park (Japan), SNS (USA) and ESS (Sweden).

Neutron powder diffraction is complementary technique to the X-ray powder diffraction. It permits to determine crystal and/or magnetic structure of powder or polycrystalline materials, analyse their phase composition, study phase transitions in-situ , etc.

Neutron based studies permits the determination of the structural details and dynamics of atomis arrangements in materials from simple measurements of scattering processes. Neutrons are scattered by nuclei, are sensitive to the atomic magnetic moments, and have scattering and absorption cross-sections independent of atomic number and mass. From this description one can extract advantages of using the neutrons as a solid matter probe.

Here are some of the advantages for using the neutron diffraction technique:

- deep sample penetration - study of the changes taking place in the volume of the sample not just on the surface; possible to use closed sample environments

- see the light elements - neutrons can "see" the light elements as a hydrogen (deuterium) or oxygen; some of the elements have negative scattering length -> distinguishing elements standing beside in the periodic table

- direct interaction with magnetic structure - observation of the magnetic reflections -> study of the magnetic structure

As happened in the life some advantages can be also disadvantages. Deep sample penetration is one of this double-edge sword property. Due to this one need large sample volume for neutrons can scatter from.

Here are some disadvantages when you work with the neutron diffraction:

- large sample needed - one of the biggest disadvantage; for the good experiment we need the sample volume of few (2-3) cc

- small neutron flux - the reactor provide small neutron flux so the collecting time can be long

In the Neutron Physical Laboratory there is available neutron powder diffraction instrument called MEREDIT which is open for the scientist across the research fields. If you think that you have some interesting sample and advantages of the neutron diffraction is what you looking for please do not hesitate to contact the instrument responsible.

Because of their high penetration ability into most materials thermal neutrons have been found very useful probe in measurements of internal strains in polycrystalline samples. The neutron diffraction technique can provide information on both macro- and micro-strains. The determination of macrostrains (e=Δd/do) is based on the measurement of small angular shifts of diffraction peaks caused by small lattice-parameter variations of Δd in a sampled volume with respect to the stress-free lattice spacing do. The magnitude of stress can be calculated by using appropriate elastic moduli. Investigation of microstrains is based on the analysis of the shape of broadened diffraction profiles. Two high-resolution neutron strain scanners are available at the medium-power reactor LVR-15 in NPI Řež. The instruments are equipped with curved Si and Ge monochromators and with linear high-resolution position-sensitive detectors for fast recording of diffraction profiles.

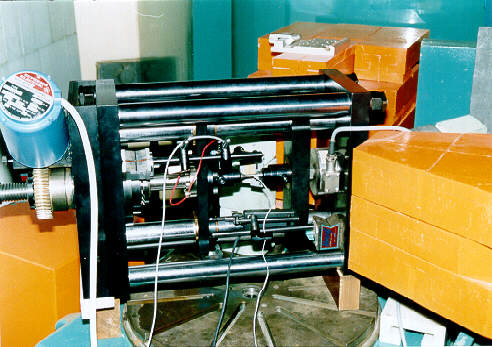

Both diffractometers operate with a sufficiently high Δd/d-resolution of about (2-2.5)x10-3, information on microstrain state of materials could be thus received as well. Recently, a lot of work has been done investigating the distribution of residual strains resulting from different technological treatments as well as phase specific strains in multiphase materials and in composites. Nowadays, of special interest are deformation tests realized in situ at the neutron beam. Such experiments are possible due to the small and compact deformation rig enabling both tensile and compressive tests up to maximum loading of ±20 kN which can be easily mounted at both strain scanners. In this case, we focus mainly on studies of duplex stainless steels and shape memory alloys.

| [1.1] | J. Kulda, P. Mikula, P. Lukas, M. Kocsis: Physica B180-181 (1992) 1041. |

| [1.2] | M. Vrana, P. Mikula, P. Lukas, J. Kulda: Nucl. Instr. Meth. A338 (1994) 125. |

| [1.3] | P. Mikula et al . : J. de Physique IV 3 (1993) 2183. |

| [1.4] | P. Klimanek, T. Kschidock, P. Lukas, P. Mikula, A. Mucklich: J. de Physique IV 3 (1993) 2143. |

Small-angle neutron scattering ranks among several techniques (e.g. X-ray small angle scattering, electron microscopy) widely used for investigation of condensed matter structure. The SANS technique is concerned with the measurement of structures within the size range 30-105 Å. This size range corresponds to momentum transfer Q values ranging from 105 to 0.3 Å-1. For measurements in the range of small Q values, we employ the double-crystal (DC) nondispersive setting using elastically bent perfect crystals.

We keep the priority in employing elastically bent perfect crystals in the DC setting for measurement in the Q range from 10-4 to 10-2 Å-1 (medium resolution range). This experimental arrangement makes possible easy variation of the resolution according to the experimental requirements [3.1]. Feasibility of this instrument has been demonstrated in the practical use since the year 1983 [3.2, 3.3]. At the beginning of the year 1993 we introduced into a routine operation an improved version of the DC diffractometer when employing the second crystal (analyzer) in the fully asymmetric diffraction geometry. In such a way the angular deviation of the scattered neutrons is converted to the linear spatial scale [3.5, 3.6] which in fact enables us to use a linear position sensitive detector (PSD) and to acquisite efficiently the SANS spectrum [3.7, 3.8]. Promising properties of the new device has been proved by investigations of porous structure of Vycor glasses [3.9] and of a morphology of precipitates in the creep exposed CMSX2 single crystal [3.10] (in collaboration with University of Ancona, Italy).

In the last years, we use a complementarity of DC arrangement and conventional SANS facilities (HMI Berlin, KFKI Budapest) in material research of single-crystal nickel-based superalloys [3.11,3.12] and of plasma sprayed materials which are both technologically very important materials.

The two-phase microstructure consisting of g� precipitates growing in the gamma phase matrix is the basic feature which determines a high creep-resistance of nickel-base superalloys, the materials frequently used in aircraft and land-based turbines. Outstanding high-temperature mechanical properties of these materials strongly depend on the morphology of the precipitates and thus also on the applied heat treatment. The morphology is conventionally studied by transmission electron microscopy, however, this and other standard methods of materials science do not usually characterize the microstructure completely. SANS, which provides bulk-averaged information, has been found to be a powerful tool for investigation of microstructural inhomogeneities in single-crystal alloys. A number of studies documents an applicability of SANS particularly to investigation of precipitation in single-crystal Ni-base alloys.

Recently, our research has been focused to investigation of precipitate microstructure in ZS26, CMSX3, SC16 and SCA superalloys. Anisotropic 2D SANS curves provide information on the average shape of the ordered cuboidal g�-precipitates [3.13,3.14,3.15,3.16] (the asymptotic region of a SANS curve) as well as on the precipitate dimension and distances between them [3.12,3.14,3.15] (central part of the scattering curve). The original data evaluation procedure [3.17,3.18] (numerical modeling and fitting) allows - in many cases - to estimate well the volume fraction of the precipitates even without the knowledge on the scattering contrast. The SANS results are usually related to the used heat treatment procedures or creep expositions. In the case of SC16, the SANS measurement revealed the presence of well oriented additional phase [3.19, 3.20, 3.21] which could not be effectively characterized by the other experimental methods. Detection of this additional phase is important even it occupies only small volume fraction because it can cause initialization of cracks in the material.Our investigations were also recently extended to non-destructive studies of lamellar precipitates resulting from high-temperature creep-exposition of superalloys.

The plasma-sprayed materials find various applications in chemical, ceramic, aerospace industries, medicine and other fields in the form of coatings or even self-supported components, which can improve substantially the thermo-mechanical, chemical or electrical properties of final products. These materials are characterized by the presence of wide spectrum of pores and cracks, which mainly determine the material properties. The knowledge of porosity characteristics and their dependence on the conditions of matarial preparation has therefore essential importance. SANS is one of the techniques suitable for the characterization of porosity in mesoscopic size range. However, evaluation of SANS measurements is typically complicated by the presence of strong multiple scattering. The measurements at conventional (�pinhole�) instruments were mostly limited to the determination of specific surface of pores, which can be evaluated from outer parts of scattering curve, usually not affected by multiple scattering. The double-crystal (DC) diffractometer (DN-2) makes high-resolution SANS measurements possible at short neutron wavelengths, where the influence of multiple scattering is much weaker. In 1998, we have finished the development of the software for SANS data evaluation in multiple scattering regime. This program combines standard indirect Fourier transform method with formalism for calculation of multiple scattering and allows to fit model microstructure (e.g. polydisperse system of spheres) on the data measured at DC instruments. By this method, we could first time evaluate size distribution of pores in plasma-sprayed alumina in the size range from 100 Å to 1 mm and to study evolution of porosity in dependence on the thermal treatment of the samples. In the overlapping regions of scattering vectors, the results are in good agreement with measurements on identical samples performed at pinhole instruments at KFKI Budapest and NIST Gaithersburg [3.11, 3.22-3.24].

| [3.1] | J. Kulda, P. Mikula: J. Appl. Cryst. 16(1983)498. |

| [3.2] | P. Mikula, V. Wagner, R.Scherm: J. Appl. Cryst. 24 (1991)298. |

| [3.3] | F. Eichhorn, J. Kulda, P. Mikula: Phys. Stat. Sol. 82(1984)K141. |

| [3.4] | P. Bianchi et al.: Mat. Sci. Forum 27/28 (1988)429. |

| [3.5] | P. Mikula, P. Lukas, F. Eichhorn: J. Appl. Cryst. 21(1988)33. |

| [3.6] | P. Mikula, P. Lukas, J. Kulda, F. Eichhorn: Physica B156-157(1989)605. |

| [3.7] | P. Lukas, P. Mikula, J. Kulda, J. Saroun, P. Strunz: Physica B180-181(1992)984. |

| [3.8] | P. Lukas, P. Mikula, J. Saroun, P. Strunz: Nucl. Instr. Meth. A338(1994)111. |

| [3.9] | P. Strunz et al .: Journal de Physique IV 3 (1993)1439. |

| [3.10] | Strunz P., Lukáš P., Mikula P., Šaroun J., Keilová E. and Koèík J., Acta Physica Hungarica 75 (1994) 279-284. |

| [3.11] | Strunz P., Šaroun J., Mikula P., Lukáš P. and Eichhorn F., J. Appl. Cryst. 30 (1997) 844-848. |

| [3.12] | P. Strunz, A. Wiedenmann, J. Zrník and P. Lukáš, J. Appl. Cryst. 30 (1997) 597-601 |

| [3.13] | P. Strunz, J. Zrník, A. Wiedenmann and P. Lukáš, In Proc. of EUROMAT 95, Padua/Venice (Italy), 25-29.9.1995, p. 499-502, 1995, Milano: Associazione Italiana di Metallurgia. |

| [3.14] | Gilles R., Mukherji D., Strunz P., Wiedenmann A. and Wahi R. Zeitschrift fuer Metallkunde 88 (1997) 518-521. |

| [3.15] | Gilles R., Mukherji D., Strunz P., Wiedenmann A. and Wahi R., Physica B 234-236 (1997) 1008-1010. |

| [3.16] | Strunz P., Zrník J., Lukáš P., Wiedenmann A., Mikula P. and Gilles R., Proceedings of EUROMAT'97, vol. 4 (1997) 93-96, ed.by L. A. J. L. Sarton and H. B. Zeedijk, NL Soc. for Mat.Sci. |

| [3.17] | P. Strunz and A. Wiedenmann, J. Appl. Cryst. 30 (1997) 1132-1139 |

| [3.18] | Strunz P., Materials Structure in Chemistry, Biology, Physics and Technology (Bulletin of the Czech and Slovak Crystallographic Association) 4 (1997) 136-143. |

| [3.19] | Gilles R., Mukherji D., Strunz P., Barbier B., Wiedenmann A. and Wahi R. Scripta Mat. 38 (1998), 803-809. |

| [3.20] | Gilles R., Mukherji D., Strunz P., Wiedenmann A. and Wahi R. Physica B 241-243 (1998), 348-349. |

| [3.21] | Gilles R., Mukherji D., Strunz P., Lieske S., Wiedenmann A. and Wahi R.P. Scripta Materialia 39 (1998) 715-721 |

| [3.22] | J., Saroun, F., Eichhorn, A., Hempel, P., Lukas, B., Kolman, K., Neufuss, P., Mikula, P., Strunz, Physica B, 234-236, 1997, 1011- 1013. |

| [3.23] | Mikula P., Lukáš P., Strunz P., Saroun J., Vrána M., Dlouhá M. and Vratislav S., Physica B (1998) 241-243. |