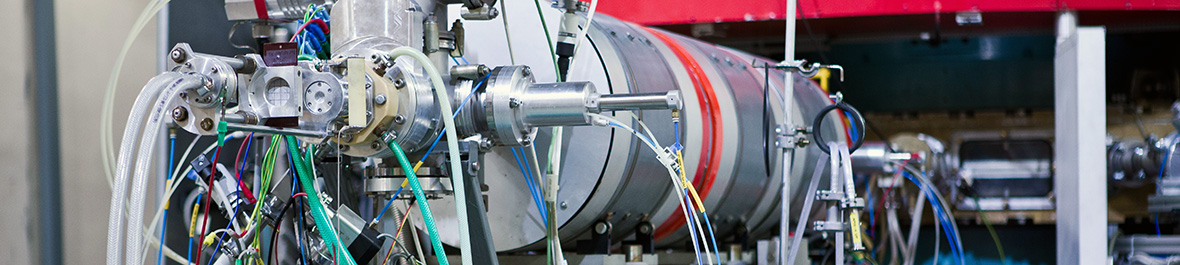

Strain Diffractometer (TKSN-400)

TKSN 400 is a high resolution two-axis diffractometer optimized for investigation of internal stresses in polycrystalline materials. Due to its equipment, the instrument is dedicated especially for thermo-mechanical testing of materials, i.e. to study the deformation and transformation mechanisms of modern types of newly developed materials. Neutron diffraction performed in situ upon external loads, brings a wide range of valuable structural and sub-structural parameters of the studied material which is easy to correlate with parameters of external loads.

Instrumental parameters

| Monochromator | horizontally and vertically focusing, elastically bent Si single crystals | |

| Wavelength | 1 Å ≤ λ ≤ 3.7 Å (standardly used λ=2.3 Å with second harmonics λ=1.15 Å) | |

| Neutron flux at the sample position | 105n cm2 s-1 at λ=2.3 Å | |

| Angular range | 25°< 2θ < 90° | |

| Resolution | 2x10-3 ≤ Δd/d ≤ 3x10-3 |

Equipment

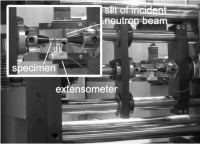

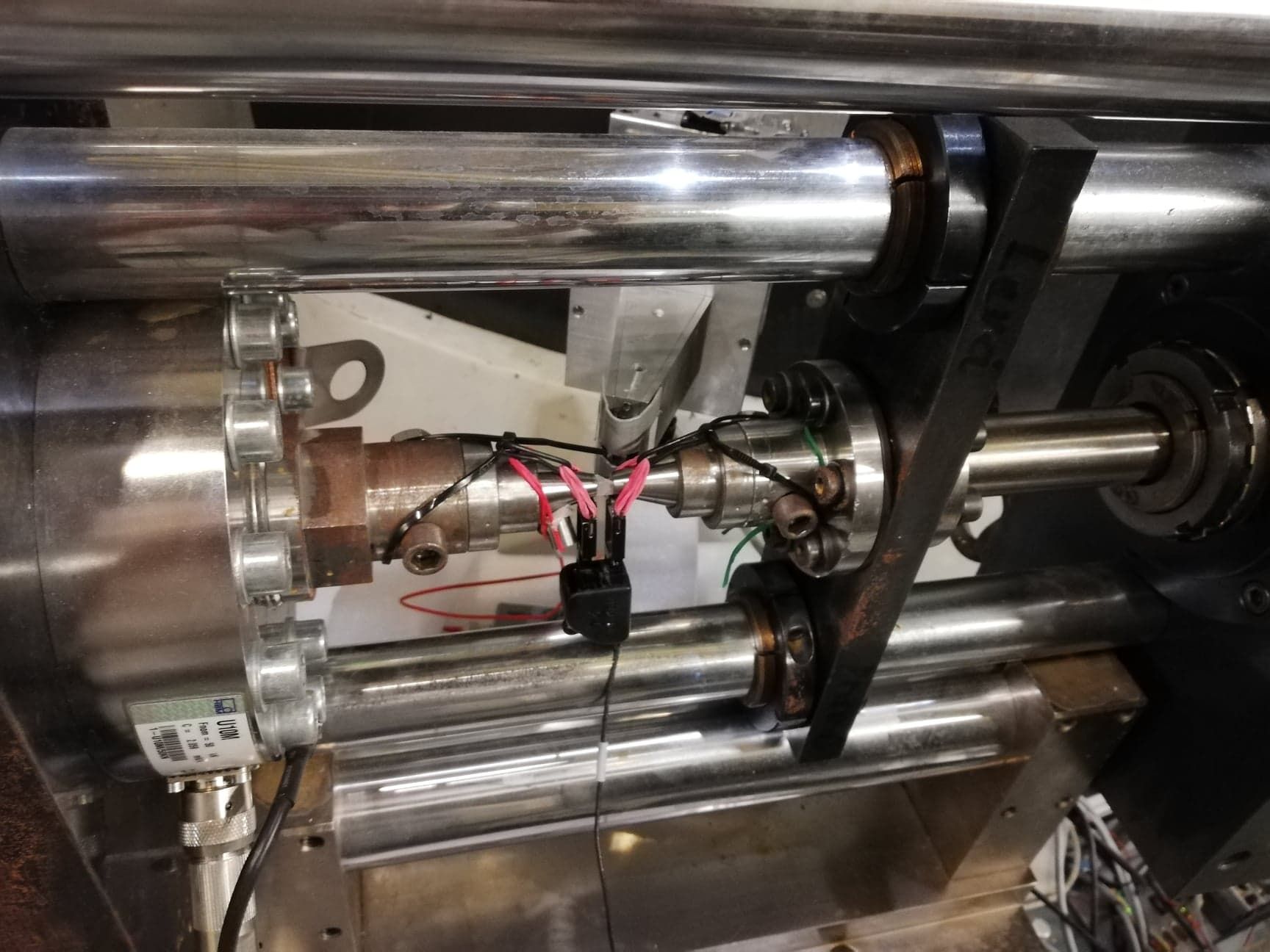

- Deformation machine for uni-axial loading (tension, pressure) ± 20 kN

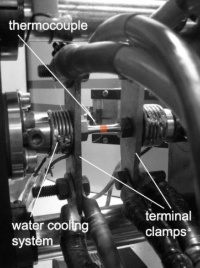

- Resistant heating (T < 1200°C)

- Hot-air heating (T < 300°C)

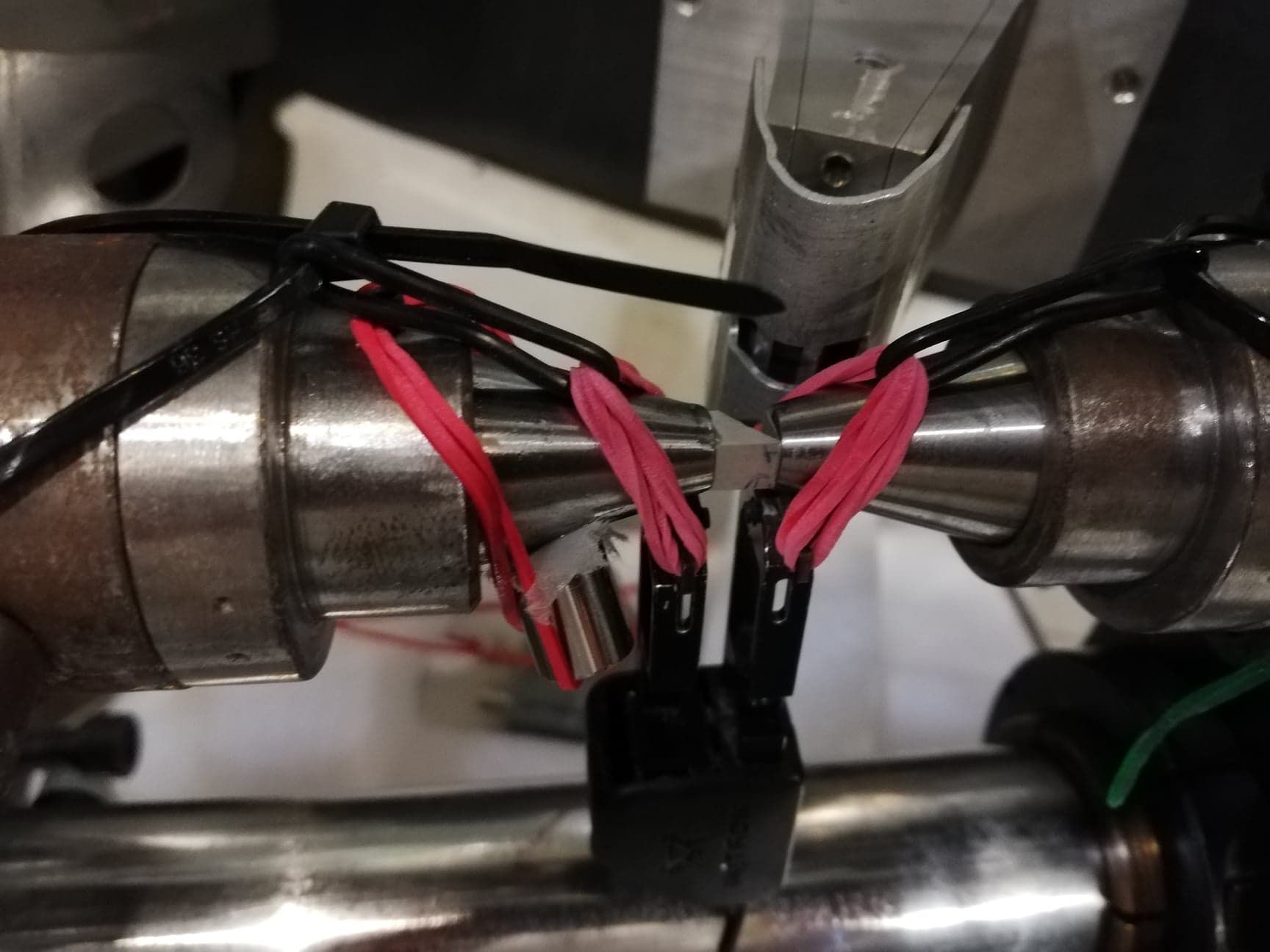

- Miniature deformation machine for uni-axial loading (tension, pressure) ± 10 kN

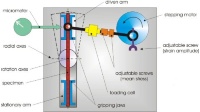

- Eulerian cradle: inner diameter of 400 mm, 0° < χ < 160°, 0° < φ < 360°

- Deformation machine for bending loading, maximum cycling frequency of 27 Hz

- In-situ acoustic emission measurement during loading test. Physical Acoustics PCI-2 board. AE senzor frequency range: 100–1200 kHz