Beer

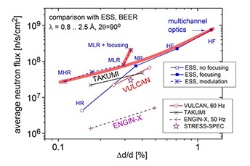

BEER will become a world-leading instrument for engineering applications with several unique features, including very high neutron flux allowing fast dynamical experiments as well as extended flexibility, which allows users to adapt experiment conditions to their needs.

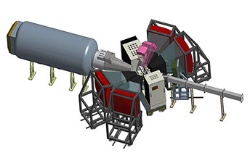

Building of this neutron diffractometer is a joint project of Czech and German in-kind contributions to the ESS.

The instrument is unique within the experimental facilities at ESS by its focus on industrial applications. It will enable research in engineering materials with various degrees of complexity as for example in-situ and in-operando experiments for material characterization, thermo-mechanical processing or joining of materials.

These include studies of phase transformations, residual stresses and textures evolution, precipitates formation and dissolution and other microstructural parameters at industrially relevant thermo-mechanical conditions and time scales.

|

|

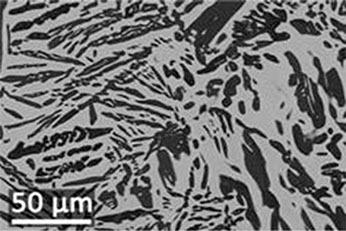

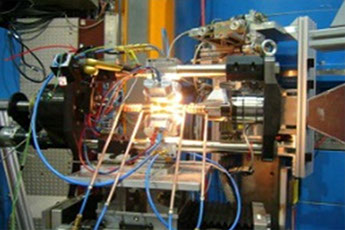

In-situ thermo-mechanical testingThe deformation mechanisms and microstructure in advanced Mg or TiAl alloys need to be better understood in order to improve their properties. |

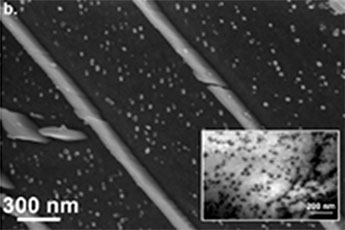

Microstructure evolutionsimultaneous study of structure, micro-strains and precipitation in advanced materials. |

|

|

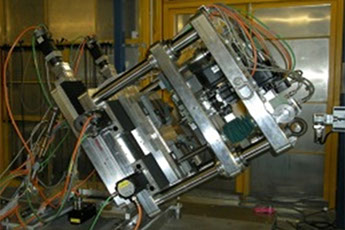

Stress rigs and furnacesuniaxial and biaxial loading + high and low temperature capability. |

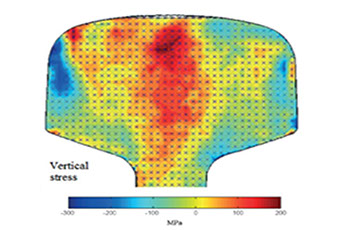

Residual stress analysismaps of residual stress distributions for assessing the performance of materials in large components under service conditions. |

|

|

Gleeblephysical simulator of materials processing: very fast heating and deformation capabilities, forging, melting |

Welding experimentsfriction stir welding and laser beam welding |