HK4 - Strain scanner

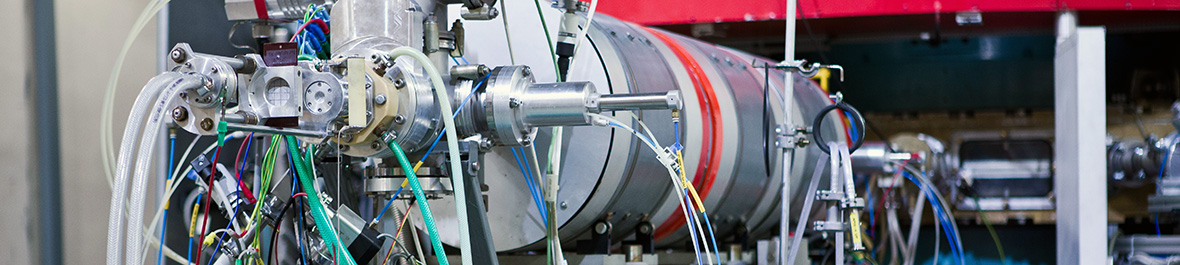

The two-axis diffractometer SPN-100 is a 2-axis neutron diffractometer usually used for mapping of residual strains inside polycrystalline materials.Typical examples are residual strains developed in the course of welding or strains accumulated during processing and/or usage of engineering components.

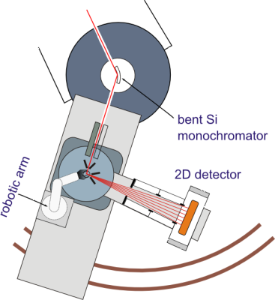

SPN-100 is a double axis diffractometer employing elastically bent perfect Si crystal as a focusing monochromator. The instrument is designed for measurements of residual strains by accurate evaluation of positions of a selected diffraction peak from small material volume defined by a set of input and output slits. The diffractometer has a changeable monochromator take off angle and can be set and operated at a suitably chosen wavelength in the range 0.1 nm to 0.235 nm. In the case of α-Fe and γ-Fe samples, it usually operates at the neutron wavelength of 0.23 nm, providing a good resolution after diffraction on the α-Fe(110) and / or γ-Fe(111) lattices planes.

Layout

Parameters

| Type of instrument | Two-axis diffractometer |

| Source | LVR-15, 10 MW research reactor |

| Beam tube | Horizontal channel No. 4 |

| Monochromators | Bent Si(111) and Si(220) |

| Take-off angle (range) | 30 – 60° |

| Neutron flux on specimen | 2 × 105 cm−2·s−1 |

| Incident wavelength | 1.0 – 2.35 Å |

| Detector | 2-D Position Sensitive Detector, 3He, active area of 230 × 230 mm2, resolution 2 x 2 mm2. |

| Sample - detector distance | 1000 mm |

| Beam defining optics | Cd slits in the incident and diffracted beams |

| Specimen weight capacity | XYZ stage: up to 50 Kg Robotic arm: up to 7 Kg |

Sample positioning

For sample positioning, in addition to standard x-y-z translation stage, a six-axis robotic arm is available allowing more flexible manipulation of complex-shaped samples and automation of strain measurements.

Sample positioning by robotic arm video

Selected publications

- Correlation of magnetic properties and residual stress distribution monitored by X-ray and neutron diffraction in welded AISI 1008 steel sheets. Vourna, P., Hervoches, C., Vrana, M., Ktena, A., Hristoforou, E. (2015) IEEE Transactions on Magnetics, 51 (1), art. no. 7029219.

- Residual stresses determination by neutron diffraction in a 100Cr6 chromium steel bearing ring. Rogante, M., Martinat, G., Mikula, P., Vrána, M. (2013) Kovove Materialy, 51 (5), pp. 275-281.

- Residual stresses assessment in coated materials: Complementarity between Neutron and X-ray techniques. Rogante, M., Mikula, P., Vrána, M. (2011) Key Engineering Materials, 465, pp. 259-262.

- Suppression of surface effect by using bent-perfect-crystal monochromator in residual strain scanning. Vrána, M., Mikula, P. (2005) Materials Science Forum, 490-491, pp. 234-238.

- High-resolution neutron diffraction for nondestructive analysis of residual stresses in polycrystalline materials. Mikula, P., Lukáš, P., Vrána, M. (2005) Applied Mechanics and Materials, 3-4, pp. 331-336.